Introduction

Process Safety, like Personal Safety, depends on everyone being fully committed to playing their part in minimising the possibility of major accidents occurring.

This unit explains how individual employees can develop their own individual Process Safety leadership improvement plan. This is a short unit, as the emphasis here is on the task set for you.

9.1

Process Safety Improvement Plans

The basic principles of PSIP

COMAH Regulations

A key feature of the COMAH regulations is that facility operators define and commit to implementing an improvement plan to reduce risk to ALARP

Progress against such improvement plans should be rigorously reviewed at regular intervals.

People at all levels – senior management, operators, outside contractors, etc. - can make their individual contribution towards establishing and maintaining high standards of safety.

An effective way of doing this is for individuals to generate their own Process Safety Improvement Plans to define and commit to the actions required to improve their individual contribution to Process Safety. This is, in effect, a practical way of getting into action.

9.2

Process Safety Improvement Plans

Action plan

Setting parameters

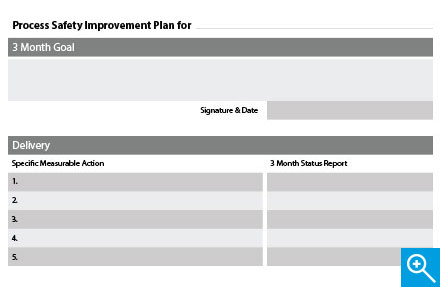

In the first instance, a PSIP should have a short time horizon.

You should establish a goal within that time horizon.

Your personal target should be defined.

Delivery

Decide what needs to be done to achieve this.

Define the process through SMART actions (Specific, Measurable, Agreed, Realistic, Timebound)

Assess your progress at least monthly.

A formal review should take place at the end of 3 months.

9.4

Process Safety Improvement Plans

Sample Templates

An example of a PSIP template for Instrument Maintenance Technicians and Control Room Operators.

Download the two sample templates and try to fill in the two templates, using your own company as a reference point.