Introduction

In this unit you will learn about how a complete and integrated Process Safety Management system can be developed, with a particular emphasis on Risk Identification and Assessment and Hazard identification and risk assessment.

Some of the elements in this unit are looked at again in more detail in unit 7.

3.1

Key elements of an effective process safety management system

Four Accident Prevention Pillars

The Basic Components

There is broad agreement on the basic components of a Process Safety Management system, although there are minor variations in the way different bodies define it.

The Chemical Centre for Process Safety (CCPS, see reading list) specifies that a complete PSM system should be built on the four accident prevention pillars.

3.2

Key elements of an effective process safety management system

Four Focus Areas

The Basic Components

The Energy Institute, in its High Level Framework for PSM, outlines four focus areas:

3.3

Key elements of an effective process safety management system

Comparison of Prevention Pillars & Four Focus Areas

Compare the two, and you’ll see that they’re saying the same thing in a slightly different way.

Chemical Centre for Process Safety

Accident Pillar 1

Commit to Process Safety

Accident Pillar 2

Understand the Hazards & Risks

Accident Pillar 3

Manage Risk

Accident Pillar 4

Learn from Experience

The Energy Institute

Focus Area 1

Process Safety Leadership

Focus Area 2

Risk Identification and Assessment

Focus Area 3

Risk Management

Focus Area 4

Review and Improvement

3.4

Key elements of an effective process safety management system

The Energy Institute’s 4 Focus Areas

A combined total of 20 elements sit beneath each of the 4 focus areas.

Each of these elements has to be effectively managed to create a complete and fully effective Process Safety Management System.

Let’s look more closely now at the 4 Focus Areas provided by The Energy Institute, and the elements within each Focus Area.

-

Click on the targets below for more information.

3.5

Key elements of an effective process safety management system

Case studies: linking theory with practice

Reaction to Buncefield

Given that the purpose of this course is to prepare you for the real world of Process Safety Management, it’s important that you make the link between the theory and the practice.

In other words, in this area, how do the Focus Areas and the elements within them apply to day-to-day operations in the chemicals industry?

As you’ve already seen, case studies play a major role in this course, and we’ll now take a second look at the Buncefield incident in 2005.

After you have watched it, there is a simple exercise which will help you to make the link between theory and practice.

3.6

Key elements of an effective process safety management system

Case studies: linking theory with practice

The 3 key questions that the HSE referred to can be linked to the Energy Institute 4 Focus Areas.

Do we understand what could go wrong?

Do we know what our systems are to prevent this happening?

Do we have information to assure us that they are working effectively?

-

For further reading download the files.

3.7

Key elements of an effective process safety management system

Hazards and Risks

Key Elements

To illustrate the concept of key elements, we now need to take a closer look at one Focus Area (Risk Identification and Assessment) and one element within that Focus Area (Hazard identification and risk assessment).

This element can be considered in two parts (A & B).

Part A

Understand how to identify hazards associated with hazardous substances and process plant

Part B

Understand how to assess the risks associated with hazardous substances and process plant

3.8

Key elements of an effective process safety management system

Case studies: linking theory with practice

Part A: Identifying Hazards

It’s important to understand how to identify hazards associated with hazardous substances and process plants.

Important Advice and Definitions

The tabs below contain some important terms and definitions linked to Process Safety Management.

The Health and Safety Executive define hazard as: Anything that may cause harm e.g. chemicals, electricity, working from ladders, noise etc.

In the context of process safety we can consider a hazard to be: Anything that can lead to catastrophic accidents particularly structural collapse, explosions, fires and toxic releases associated with loss of containment of energy or dangerous substances.

An incident/accident, as defined in the COMAH regulations, means “an occurrence (including in particular, a major emission, fire or explosion) resulting from uncontrolled developments in the course of the operation of any establishment and leading to serious danger to human health or the environment, immediate or delayed, inside or outside the establishment and involving one or more dangerous substances

Harm can be to people and/or the environment.

In order to identify hazards, you must be able to classify dangerous substances. in other words, you have to know what you’re processing.

3.9

Key elements of an effective process safety management system

Hazards and Risks

Identify hazards within

actual events

These three videos document examples of incidents where companies had failed to identify hazards, and this led to major explosions and fires.

As you watch the video clips, think about what the hazards were that the companies failed to identify, and how that links back to the 4 Focus Areas and the individual elements.

3.10

Key elements of an effective process safety management system

Hazards and Risks

Classification of Dangerous Substances

An important pre-requisite of hazard identification is a detailed knowledge of dangerous substances, and the effect on people and the environment of major accidents involving these substances.

![]() You should therefore devote additional time offline to studying the technical terms and definitions contained in the ‘Dangerous substances’ PDF glossary.

You should therefore devote additional time offline to studying the technical terms and definitions contained in the ‘Dangerous substances’ PDF glossary.

-

For further reading download the files.

3.11

Key elements of an effective process safety management system

Hazards and Risks

Loss of Containment

A key concept in Process Safety Management is loss of containment. This describes a situation where dangerous substances (eg. liquids, gases, electricity) escape from pipes, pumps, tanks, containers, etc. It also relates to incidents where solids (eg. metal structures and equipment) are projected through the air, fall from height, etc. In the vast majority of major incidents, loss of containment is the principle cause.

Loss of Containment Examples

Example 1Overpressure leading to mechanical failure, High velocity and/or large mass projectiles, High temperature releases

Example 2Rotating equipment failure, High velocity and/or large mass projectiles

Example 3Equipment falling from heights

Example 4Electricity Leakage

3.12

Key elements of an effective process safety management system

Hazards and Risks

Loss of containment of Energy

A detailed knowledge of the most likely causes of loss of containment is another essential pre-requisite in the process of identifying and understanding hazards.

![]() So, again, you should devote additional time offline to studying the technical terms and definitions contained in the ‘Likely causes of loss of containment’ PDF glossary.

So, again, you should devote additional time offline to studying the technical terms and definitions contained in the ‘Likely causes of loss of containment’ PDF glossary.

-

For further reading download the files.

3.13

Key elements of an effective process safety management system

Hazards and Risks

Hazard Identification Techniques

Any Hazard Identification process will involve a mix of received wisdom, established practices and current experience: bringing together theory and practice.

As with any industry involving complex operations, different hazard identification techniques have evolved. In this section we look at three of them.

The first two rely heavily on the experience of the team involved in the process.

3.14

Key elements of an effective process safety management system

Hazards and Risks

Hazard Identification Techniques

HAZOP differs from the first two approaches because it is very structured and formalised.

See below for key terms.

3.15

Key elements of an effective process safety management system

Hazards and Risks

That concludes Part One.

A recap - you will remember that one of the four Energy Institutes Focus Areas we looked at is Risk Identification & Assessment

One element within this Focus Area is Hazard identification and Risk assessment, which we have divided into two parts:

In Part One we looked at how to identify hazards associated with hazardous substances and process plant

In Part Two we turn our attention to how to assess the risks associated with hazardous substances and process plant.

3.17

Key elements of an effective process safety management system

Hazards and Risks

Understanding Risk

Risk is a function of Consequence and Frequency

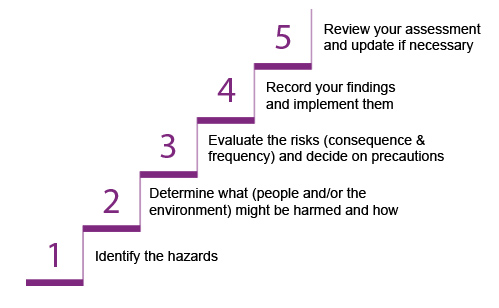

The HSE has produced a five-step approach to risk assessment.

-

For further reading click on the available resources.

3.18

Key elements of an effective process safety management system

Hazards and Risks

Risk Evaluation Techniques

There are a number of different Risk Evaluation Techniques.

- Failure Modes and Effects Analysis (FMEA)

- Layer of Protection Analysis (LOPA)

- Fault Tree Analysis (FTA)

- Event Tree Analysis (ETA)

- Human Reliability Analysis (HRA) event tree

-

For further reading download the files.

Hazard

Hazard